Did you know that there is another method for flip chip attach than the traditional C4 controlled collapse chip connection?

It is possible to replace the C4 matrix by gold stud bumps. The C4 is the traditional method by which the interconnections sites of a chip are populated with solder. The commonly used metals are the SAC alloy (tin, silver, copper) or a mix of copper, nickel and SAC. This step is done at the silicon wafer level, before chip singulation by dicing. If it is perfectly well adapted for products with thousands of interconnections, such as CMOS devices, it is not the case for the micro electromechanical systems (MEMS), in particular those with released structures.

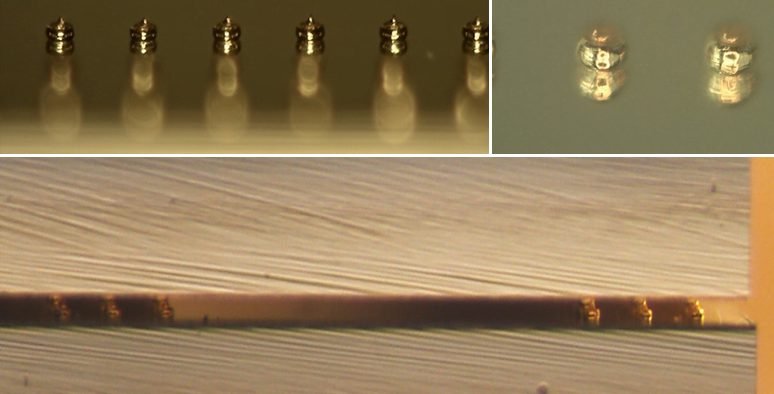

The replacement method consists of bonding gold stud bumps on the interconnection sites with a ball bonder. The component can then be flip chip assembled through thermocompression bonding. This technique is useful for MEMS, but also for low interconnection volume component.