SECS AUTOMATION USING EQUIPMENT CONNECT

Develop a Java integration server for direct SECS Communication in Equipment Connect.

TECHNOLOGICAL CHALLENGE

Users were facing some of the following challenges:

- Compliance with TS 16949 quality system requirements

- Develop a driver to communicate to fabrication tools through TCPIP and RS232 connection following SEC-I and SECS-II protocols

- Provide a framework to automate processes within the MES system

- Need for IP Protection

DEVELOPED SOLUTION

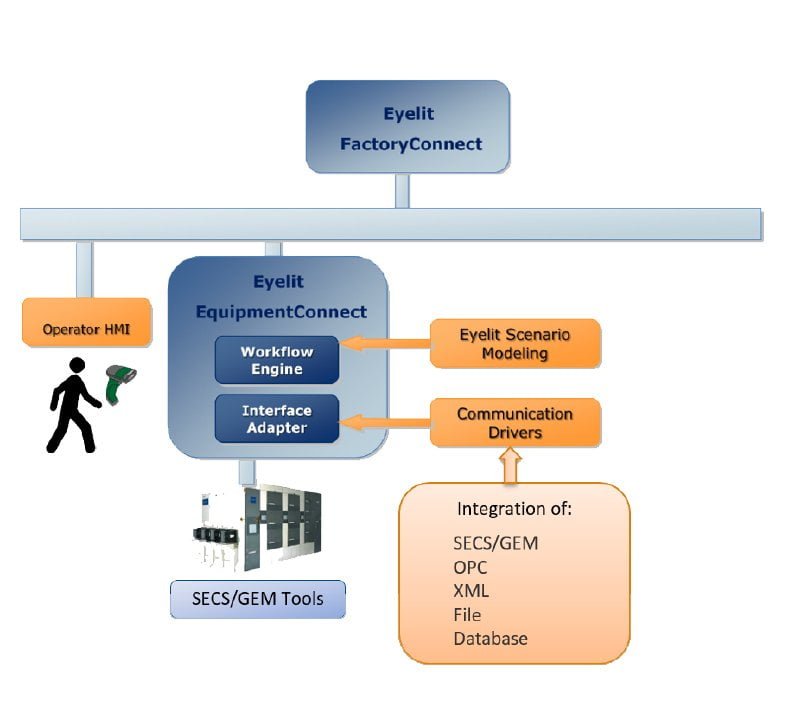

Eyelit has developed a new suite EquipmentConnect that allows for the integration of diverse manufacturing and automation systems, allowing for SECII message communication between the MES system. Following the SEMI’s SECS/GEM protocol drivers where created to connect to various Dalsa’s SECS/GEM tools, initiating a handshaking procedure to establish a stable and reliable connection. The drivers were made to be flexible enough to accommodate a wide range of tools from different manufactures. Once communication has been established, users can create Eyelit Scenario’s, which similar to a flowchart, describe the particular flow of logic that should occur in response to an event. Incoming messages from the tool would be able to trigger Scenarios to perform various automation processes on the MES system. By creating a suite of these Scenarios, users can fully automate a tool.

Description to come

GOALS

- Enable Equipment Connect to talk to SECS equipment without the need for any third-party software.

- Allow users to build their own scenarios in order to implement their own automation solution.

- Reduce operator training requirement (Next Op and follow on-screen instructions)

- Automatic data entry for SPC

- Reduce the risk of processing error

- Minimize consulting required for new scenarios

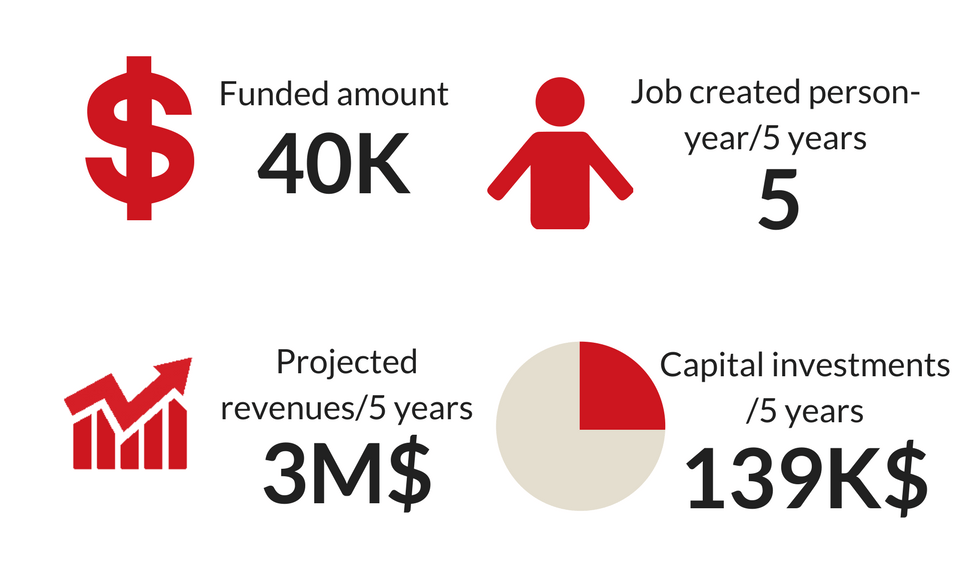

IMPACTS OF THE PROJECT: PROJECT FINANCED - YEAR 2015-2016