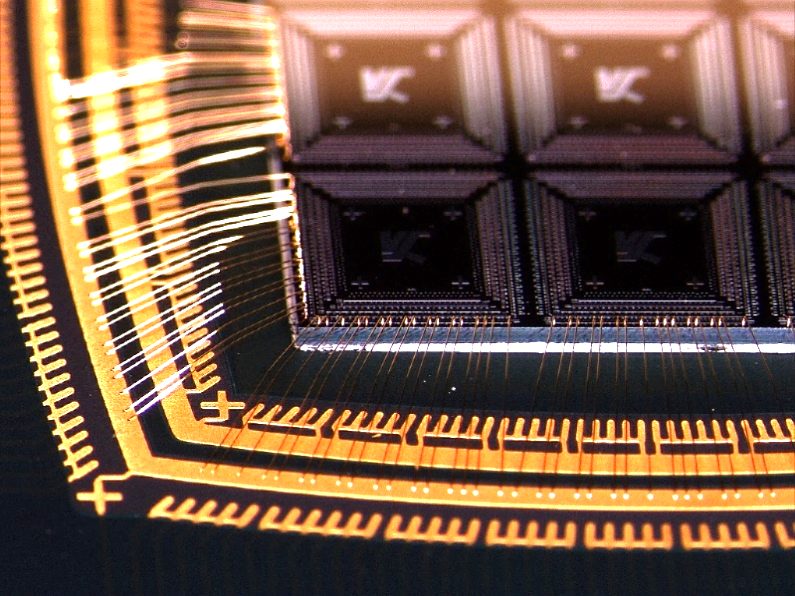

Did you know that wire bonding, although invented over 60 years ago, still requires manual threading of its automated tools?

In fact, even the more recent wire bonders still need the skillful hand of the operator to effectively thread the wire through. This means that a wire that can be as small as a third of a hair diameter (0.6 mil) needs to be manipulated by hand. And since gold is the most used metal, it means it is more of a blond hair than a dark hair. Let’s hope your glasses prescription is up to date. Fortunately, the wire spools installed on the machines of today can contain wire whose length is sometimes counted in kilometers. Threading the wire is then necessary only in cases of wire spool change and process problems.

At C2MI, we are evolving in a development environment, we are constantly testing new materials and creating programs with new types of threads, one can imagine that our team is a master in the art of threading quickly!